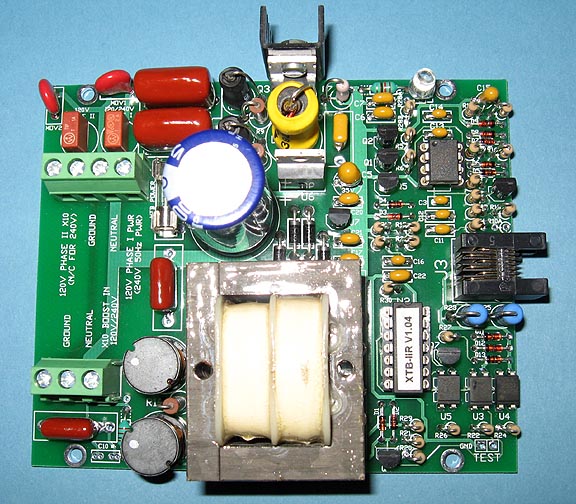

XTB-II & XTB-IIR Assembly Notes

11/16/08

Please check for the latest version before beginning assembly.

The XTB-II and XTB-IIR share the same densely populated circuit board. Some locations are left unpopulated in the XTB-II. Refer to the correct parts list for your unit. Assembly requires experience working with small components, and also the ability to correctly identify component values. A low-wattage soldering iron with a 1/16" tip is recommended. Care must be taken to not overheat the semiconductor devices. Several components have been packaged separately because identification can be difficult. Please be careful not to mix components from the different packages together.

Kits are now supplied with version 1.2 circuit boards, which contain several incremental improvements. A user-replaceable fuse has been added in series with the X10 Input receptacle to make repair easier should a heavy load be accidentally plugged into the unit. The zero-crossing reference has been modified to be insensitive to phase shift exhibited by certain power transformers. Some part numbers have been changed, so be sure to refer to the latest parts list for your board. Contact me if you need the parts list for an earlier version of the circuit board.

BEFORE ASSEMBLY

DO NOT MIX UP THE COMPONENTS. A few people have had trouble identifying components. The zener diodes have been packaged with the other semiconductors to help identify them. It is best to keep them packaged until you are ready to install them. You will need a magnifier to read the some of the part numbers - especially on the zener diodes. Be sure you have correctly identified ALL the diodes before you begin installing them. I also recommend sorting out the capacitors and resistors before soldering any onto the board. Be careful to correctly identify any 10K, 22K, or 47K resistors (orange 3rd band).

PRINTED CIRCUIT BOARD ASSEMBLY:

Please read these Detailed Assembly Instructions before beginning actual assembly. The XTB-II uses an 8-pin PIC, and you must be careful to install its socket at the "U2" end of the 14-pin footprint. Reading these notes carefully before beginning assembly should help you avoid any problems. Please refer to the appropriate parts list and printed circuit layout:

XTB-II Parts List (Version 1.2)

High resolution photographs of the assembled boards can be accessed via the XTB document Page.

Do not try to assemble the XTB-II/R with a high wattage soldering iron having a tip larger than 1/8". A variable temperature iron with a 1/16" tip works well. I recommend installing all diodes first, followed by the DIP sockets and other low-profile devices, such as U3-U5. Many components stand on end to save space. Work your way up to larger and larger components. Leave the transformer and large capacitor for last.

A dual-primary transformer may be supplied with the XTB-II/R. That can be identified by it having 4 pins on both sides. A dual-primary transformer requires two short jumpers to be installed on the reverse side of the board to connect the primaries in parallel for 120V operation. The connections are diagramed on the silkscreen. Cut-off component leads can be used for both of the short jumpers. Be sure to cut these leads flush with the top surface of the board so they donít interfere with the transformer. Note that for use on 240V, both windings must be connected in series with a single jumper.

Things to watch out for:

1) Because the version 1.2 board was designed for both the XTB-II and the XTB-IIR, a number of component locations are not populated for the XTB-II. Populate only the component locations listed on the corresponding parts list. Some part numbers have changed, so be sure to use the parts list for the version 1.2 board.

2) R10 and R28 have alternate locations in the XTB-II and the XTB-IIR. Install them in the locations defined in the parts list for your unit. Note that the body of R28 uses the same pad for both options.

3) Be careful when installing the DIP socket at U2. The XTB-II uses an 8-pin PIC, and the socket must be located at the "U2" end of the 14-pin footprint. A socket is also included for U1 to allow the possibility of a better op-amp to be used in the future. The XTB-II uses the proven workhorse LM318, but the XTB-IIR uses the higher performance (and considerably more expensive) AD817.

4) The small 220uH inductors L6 and L7 look like a resistors, and will normally be packaged with the other inductors to avoid confusion. If they accidentally get mixed up, they be identified with an ohmmeter because their resistance is about 5 ohms. R7 is similar in size, but will read only 0.2 ohms. All other resistors are 10 ohms and up.

5) Be careful to properly identify the 220 ohm resistors. The 220 ohm 1/2 watt resistors are brown carbon composition. The 220 ohm 2 watt resistors are similar in size, but are blue.

6) C5 and C15 are both 10uF tantalums. Be sure to put the 16V one at C15. The 35V tantalum may be only slightly larger than the 16V device. Kits may also be supplied with a much larger Sprague 35V tantalum.

7) Be sure J3 is firmly seated before soldering it down. Availability may force me to supply an alternate connector that does not snap in as well. If your connector is a bit loose, tack the center pin down, and then squeeze it onto the board while reheating that pin to make sure it has firmly seated. A similar approach can be used for the terminal strips. Be sure to orient them so the connection side faces the center of the board.

8) The large 3.9uH inductor at L3 is normally the API unit whose Mouser number is in the parts list. Due to availability problems, an equivalent Miller component may be supplied in its place. The Miller device has shorter leads, and it is necessary to extend one lead so it will reach the circuit board. If I have not done that on the inductor supplied with your kit, just splice in a larger cut off lead from one of the other components.

9) The version 1.2 printed circuit board can accept several different power transformers ranging in voltage from 12.6VCT to 36VCT. The transformer normally supplied for the 120V North American version is 16VCT for use with a full-wave bridge power supply. Some transformers may have dual primaries (8 total pins), and jumpers must be installed on the bottom side of the board as diagrammed for 120V or 240V operation. The 240V 50Hz version may be supplied with a 28VCT transformer for use with a full wave power supply (no D16-D17). If so, a jumper must be installed as indicated on the printed circuit board to connect the secondary center tap to ground. Verify the transformer is oriented with pin 1 near L1 before soldering it down. Depending on the transformer manufacturer, the pin numbers may be labeled on the bobbin near the pins, or there may be a mark at pin 1.

10) A light-pipe has been incorporated for this version so the LED no longer has to be mounted with full-length leads. Install the LED so that it sits about 1/4" inch above the board surface. Most LEDs have a bump in the leads at that point to keep it from seating flush to the board. The longer lead goes into the square pad (+).

XTB-II CHANGES FOR 240V 50Hz (single phase output).

Most components are now common between the units, but the 240V version uses higher voltage MOVs and fuses. The 240V version may be supplied with either a 28VCT or a 16VCT transformer. The last two digits of the part number usually specifies the voltage. Only two rectifiers (D14 & D15) are supplied with the 28VCT transformer, and the jumper that grounds the center tap must be installed for that transformer. Note: 1N4004 rectifiers are supplied for the 240V version.

Components eliminated: F2, C9, L5, R9, MOV2, J5 (front panel receptacle)

The transformer primaries must be wired in series for 240V with a cut-off component lead. (use the small holes).

Two 3-pin Phoenix terminal strips are normally supplied with the 240V 50Hz single-output kits. Be careful to locate the one at the 4-pin location as indicated on the silkscreen. The missing pin is used for the second 120V output on the North American version.

All connections are through the internal terminal strips:

Connect power in to 120/240V PHASE I & NEUTRAL

Connect X10 in to 120V/240V X10 BOOST IN & NEUTRAL

Not used: 120V PHASE II

GROUND is just a pass-through connection if needed.

Note: The X10 BOOST IN receives whatever voltage is applied to the 120/240V PHASE I terminal.

RECOMMENDED ASSEMBLY ORDER:

D1, D2, D4, D5, D6, D7, D8, D13

D3, D9, D11, D12 (check part numbers CAREFULLY)

D14, D15, (D16, D17 if supplied), L6, L7, R19

Add transformer full-wave rectifier jumper on back if no D16 or D17

Add 120V transformer jumpers on back if transformer has a dual primary (8 pins)

NOTE: for 240V install single jumper as shown.

U3, U4, U5

DIP sockets for U1 & U2 (Locate XTB-II 8-pin U2 socket at D17 end)

2-clips for Fuse 3 (Be sure to orient so the fuse can snap in)

C3, C6, C7, C12, C14, C16, C11, C13, C17, C20, C21, C22

R14, R15, R12, R16, R3, R2, R10(A/B), R11, R13

R28(A/B), R5, R6, R17, R18, R4, R31

R30, R27, R24, R22, R26, R29, R21 (R20 is not used)

NOTE: no 1/4W resistors should be left

C15 (C15 is marked 16V, be sure of polarity)

F1, F2, MOV1, MOV2

R1, R8, R9, R7

J3 (Make sure it is fully seated onto the board before soldering)

L1, L2 (2 large round inductors with short leads)

R23, R25, C5 (be sure of C5 polarity)

LED D16 (mount about 1/4 inch above circuit board)

J1, J2 (Make sure they are fully seated onto the board before soldering)

C1, C2, C4, C8, C9 (C4 ceramic won't quite seat flush with the board)

L4, L5

U7 (small 5V regulator that looks like a transistor)

Q1, Q2, Q4, Q5, Q6, Q7

U6 (large 15V regulator - be careful not to confuse with Q3)

Add heat sink to back of Q3 (fins out) & install. Fins point away from board

L3

X1 Transformer (pin 1 at square pad, make sure jumper(s) are installed if required - see 9 above)

C19 (be sure negative (-) stripe is toward terminal strips

Plug U1 & U2 into sockets

INTERWIRING & FINAL ASSEMBLY:

120V units are normally supplied with a 2-pin polarized AC receptacle for the cover. Cut two 6" pieces of insulated wire, strip 1/4" of insulation, and tin. Solder one end of each to the 2-pin receptacle, and insulate with heat shrink sleeving (white to the wider prong). Snap into the Polycase cover. Leave the red lens and light-pipe out for now.

Route the wires into a loop, and connect them to the 3-pin terminal strip. For the polarized receptacle, the wide prong is neutral, and the narrow prong is 120V X10 In. Snap the strain relief into the case. The board slides into the case at an angle by slipping it underneath the strain relief first. Mount it to the base with the 4 screws provided. Before placing the red and light pipe into the cover, be sure the LED is positioned so it will shine directly up into the light pipe. The LED has a narrow beam. Proper alignment is important to achieve maximum LED illumination.

Place the XTB labels centered below the receptacle on the front panel. The 24W label should warn against accidentally plugging in a heavier load. The XTB-II can actually deliver 50 watts to that receptacle, but the cost of creating new custom labels for this unit was prohibitive.

TEST & OPERATION:

NOTE: 120V Phase I and Phase II are assigned different pins from the 1.0 board. The silkscreen labeling is correct. Consult the layout diagram if the silkscreen labels are hard to read.

As a final check before applying power, verify the resistance between the Phase I and Neutral AC inputs measures about 160 ohms (600 ohms for the 240V 50Hz version). If it reads MUCH lower, the transformer may have been installed backwards.

Once assembled, the unit can be checked by just connecting a 2-wire cord to 120V Phase I and Neutral on the 4-pin terminal strip. For your safety, use a polarized plug, and verify the wide prong is connected to neutral. A maxicontroller can be plugged into the X10 input receptacle, and you should have some means of monitoring signal level. Plug the unit into AC power. The LED should flash briefly after about a second. The internal oscillator in some PICs has been slow to start, and cycling power again should get it going. The unit should transmit any signals received on its X10 input receptacle while in the default X10 boost mode. The LED will flash in response to any transmitter input. If the LED is constantly illuminated, or does not flicker at all, then something is wired wrong.

NOTE: Do not operate the XTB-II in the default X10 boost mode without having a transmitter plugged into the X10 input receptacle. Without a transmitter load, certain types of line noise might couple back into the driver stage and cause it to switch on.

Please refer to the appropriate Description and Mode Programming Documents for further information on how best to configure the XTB-II or XTB-IIR for your particular installation:

Please contact me if you have any questions at: jeff@jvde.us

If you don't receive a response within 24 hours, try: JeffVolp@att.net

XTB-IIR Assembled PCB

JV Digital Engineering XTB Home Page

[XTB & XTB-II/R Overview] [XTB Ordering Info] [X10 Troubleshooting Info]